1,General principles of production line

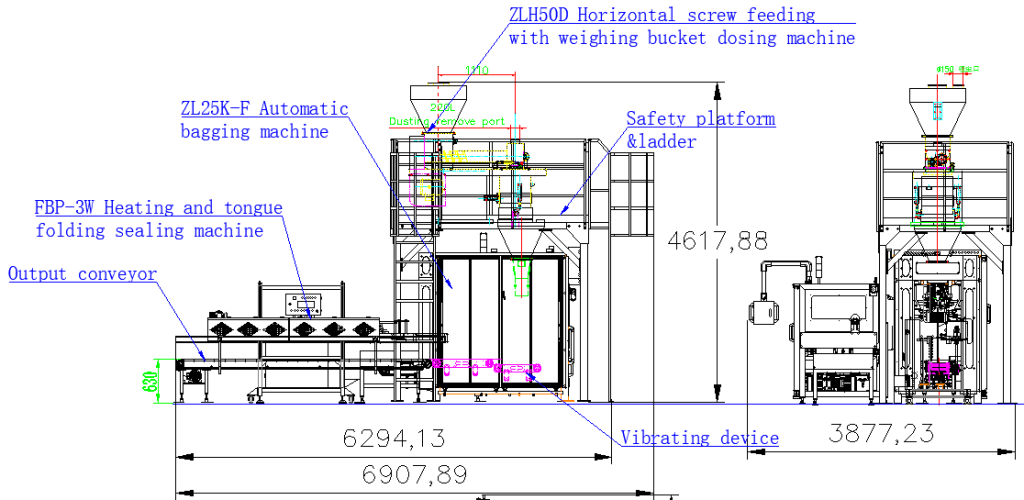

This line is special design for automatic weighing the bulk powder filling bagging in to 15-25kg karft paper bag then sealing the bag .According the client requirement we also need offer the automatic weight check ,metal detector and palletizing .The seller completed the design, manufacturing and supply of the production line in strict accordance with the technical requirements and combined with its own packaging line design experience in the sugar industry.

Automatic packaging machine can realize automatic measurement, automatic bag loading, automatic filling, automatic heat sealing, sewing and wrapping, without manual operation. Save human resources and reduce long-term cost investment. It can also complete the whole production line with other supporting equipment. Mainly used in various powder material like chemical powder ,Pesticide powder,Milk powder Protein powder etc .

Glavne karakteristike

Automatic weighing, automatic bag loading, automatic bag sewing, no manual operation is required; Touch screen interface, simple and intuitive operation; The unit is composed of bag preparation warehouse, bag taking and bag handling device, bag loading manipulator, bag clamping and unloading device, bag holding pushing device, bag opening guiding device, vacuum system and control system;It has a wide adaptability to the packaging bag. The packaging machine adopts the bag picking method, that is, taking the bag from the bag storage, centering the bag, sending the bag forward, positioning the bag mouth, pre opening the bag, inserting the knife of the bag loading manipulator into the bag opening, and clamping the two sides of the bag mouth with air gripper on both sides, and finally loading the bag. This kind of bag loading method does not have high requirements on the size error of the bag manufacturing and the quality of the bag itself Low bag making cost; Compared with the pneumatic manipulator, the servo motor has the advantages of fast speed, smooth bag loading, no impact and long service life;

Two micro switches are installed at the opening position of the bag clamping device, which are used to detect whether the bag mouth is fully clamped and whether the bag opening is fully opened. In order to ensure that the packaging machine does not misjudge, does not spill material to the ground, improves the use efficiency of the packaging machine and on-site working environment;

Elektromagnetni ventil i druge pneumatske komponente su zapečaćene konstrukcije, nisu izložene instalaciji, mogu se koristiti u prašnom okruženju, kako bi se osiguralo da oprema ima dug vijek trajanja.

This unit consists of a bag storage bin, bag taking and sorting device, bag loading robot, bag clamping and unloading device, bag pushing device, bag mouth guide device, vacuum system and control system.

Karakteristike

1).Wide adaptability to packaging bags. The packaging machine adopts the bag picking method, that is, the bag is taken from the bag preparation warehouse, the bag is centered and positioned, the bag is sent forward, the bag mouth is positioned, the bag is pre-opened, the bag loading manipulator inserts the knife into the bag mouth to open the bag mouth, and then Bag up.

2). The bag loading manipulator arm is driven by a servo motor. Compared with the pneumatic manipulators of most other manufacturers, it has the advantages of fast speed, smooth bag loading, no impact, and long service life.

3). The bag clamping and unloading device is equipped with two proximity switches at the bag clamping opening, which are used to detect whether the packaging bag opening is completely clamped and whether the bag opening is fully opened. This ensures that the packaging machine does not misjudge and does not spill materials on the ground, which improves the use efficiency of the packaging machine and the on-site operating environment.

4). The parameter setting of the packaging machine is completed on the touch screen. The human-machine friendly touch screen operation interface can comprehensively monitor the operating status of the entire machine. Automatic fault display and processing method prompts allow maintenance personnel to deal with the fault in the shortest time.

5) Pneumatic components such as solenoid valves and precision products such as touch screens and weighing instruments are all sealed and installed without exposure. They are suitable for use in dusty environments, which ensures that the equipment has a long life.

6) All control components and executive components of the packaging machine are produced by famous domestic and foreign companies, ensuring long-term, stable and reliable operation of the equipment.

7) It has a fault self-diagnosis function and an audible and visual alarm system to promptly alert any problems that arise.

8) The simple and convenient operating platform makes it easy for operators to operate and monitor the machine.

Tehnički parametri:

Packaging capacity :80-150bags/h

Control method Programmable controller (PLC)

Material: 304 stainless steel for material contact surface, 304 stainless steel for frame protection, etc.

Set weighing value Net weight 15-25kg/package

Air consumption ~ 600NL/min

Power supply AC 380V 50Hz ~ 15kw